Latest News

Latest News

Stay Up-to-Date with the Latest News!

Mar 26, 2024

3:18 PM

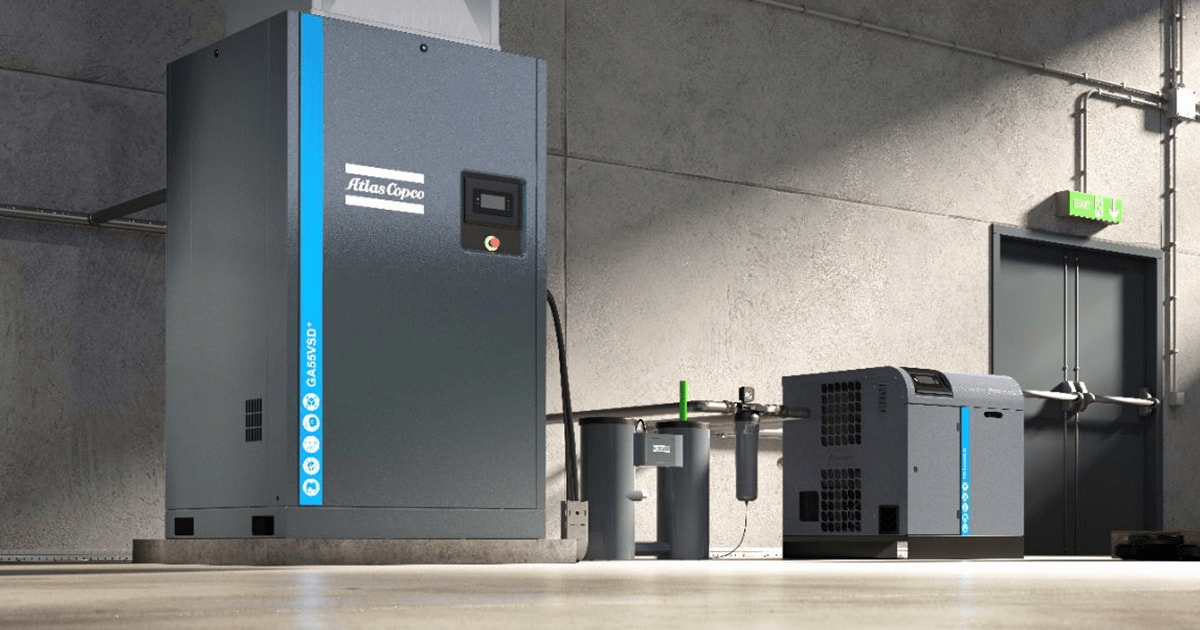

Nitrogen generation for laser cutting

Nitrogen generation for laser cutting Generating nitrogen on-site for laser applications can be cheaper and safer. Contact our experts now Why use nitrogen for laser cutting? Nitrogen is the most common assist gas used when the cut of the laser must be excellent. The process vaporizes the metal, and before the vaporized metal can re-solidify, the nitrogen gas moves it away from the cut edge. Nitrogen is also essential in: Reducing discoloration of the cut edge Establishing a barrier between atmospheric oxygen and the heated metal edge Assisting in heat dissipation, so the cut edge will cool faster Preventing oxidation to avoid problems with the finished product Helping to purge the laser beam How nitrogen prevents oxidation during laser-cutting Thanks to its inert properties, nitrogen allows the laser to operate in an oxygen-free environment without the risk of oxidation. When your application heats up and comes in contact with oxygen, a phenomenon known as oxidation occurs. This can cause a carbon layer to form on the cut edge resulting in issues such as poor product finish and adhesion problems for any coating or paint applied to the oxidised surface. How nitrogen helps to purge the laser beam To prevent the beam from distorting and to maintain power and intensity, the beam path needs to be kept clear of dirt particulates and any other contaminants that could cause it to diverge or lose power. Nitrogen is the ideal medium to use for beam guide-way purging as it is dry, clean, oil-free, and has a very low contaminant content.

Latest News

Maximize Power Plant Reliability with Atlas Copco Compressors

April 03 2024

Certified Clean Air Compressors for Pharmaceuticals

April 03 2024

Oil-Free Compressors for PET Bottle Blowing: Clean Air, Total Solutions

April 03 2024

Your Trusted OEM Partner for Compressed Air Solutions

April 03 2024

Reliable Compressed Air Solutions for the Oil and Gas Industry

Mar 27, 2024