Industry

Food and beverage

Description

Dedicated Class 0 certified compressor air systems for the food and beverage industry. Guaranteed oil-free air for safe and high-quality end products, lowest total cost of ownership.

Applications

Automation air

Compressed air is used to control the valves and actuators in automated lines for filling, packaging and bottling. With oil-free compressed air, you prevent your automation components from jamming and keep your end product safe.

Compressed air is used to control the valves and actuators in automated lines for filling, packaging and bottling. With oil-free compressed air, you prevent your automation components from jamming and keep your end product safe.

Pneumatic conveying

Compressed air is used to push powdered milk or cocoa powder along pipes. With oil-free air, you will avoid oil contaminant mixing with the powder and maintain the powder purity.

Compressed air is used to push powdered milk or cocoa powder along pipes. With oil-free air, you will avoid oil contaminant mixing with the powder and maintain the powder purity.

Cleaning air

Compressed air for cleaning bottles, packaging and moulding prior to filling. Oil in compressed air will contaminate the food containers and alter the flavour and odour of the end product, besides being a health hazard.

Compressed air for cleaning bottles, packaging and moulding prior to filling. Oil in compressed air will contaminate the food containers and alter the flavour and odour of the end product, besides being a health hazard.

Air blowing, aeration

Compressed air is pumped into a liquid to boost its oxygen content. This is used, for example, in fish farming to oxygenate water in lower layers and/or oxidize the sediments. Oil contamination in the air will kill the fish and other fauna.

Compressed air is pumped into a liquid to boost its oxygen content. This is used, for example, in fish farming to oxygenate water in lower layers and/or oxidize the sediments. Oil contamination in the air will kill the fish and other fauna.

Fermentation

Compressed air supplies oxygen to bacteria during fermentation to produce food ingredients such as citric acid, wine, yoghurt… The presence of even small oil traces will affect bacterial activity, create a substandard product and contaminate the end product.

Compressed air supplies oxygen to bacteria during fermentation to produce food ingredients such as citric acid, wine, yoghurt… The presence of even small oil traces will affect bacterial activity, create a substandard product and contaminate the end product.

Food storage

In the air separation process, compressed air is broken up into oxygen and nitrogen. The nitrogen is then used to preserve foods in cans, in larger storage facilities and in maritime transport. The air must be 100% oil-free as the nitrogen comes directly into contact with the food. Oil will also destroy the membranes in psa plants which are expensive to replace.

In the air separation process, compressed air is broken up into oxygen and nitrogen. The nitrogen is then used to preserve foods in cans, in larger storage facilities and in maritime transport. The air must be 100% oil-free as the nitrogen comes directly into contact with the food. Oil will also destroy the membranes in psa plants which are expensive to replace.

Cooling and spraying

Compressed air is used to cool down baked goods after they emerge from the oven. Contamination of the air spoils the end product leading to rejections and production losses.

Compressed air is used to cool down baked goods after they emerge from the oven. Contamination of the air spoils the end product leading to rejections and production losses.

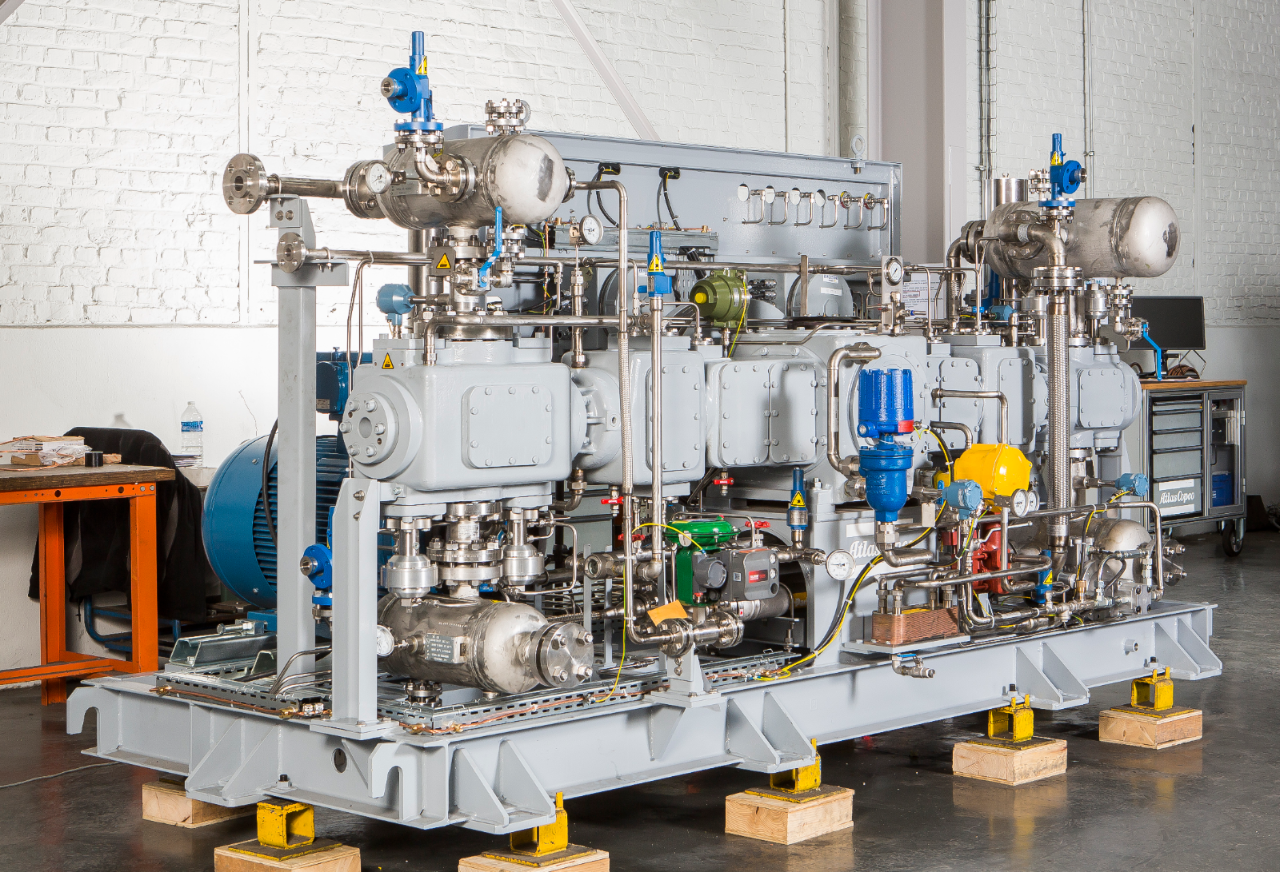

Compressed air solutions

Oil-free screw air compressors ZR & ZT (VSD)

Oil-free screw air compressors ZR & ZT (VSD) Oil-free air centrifugal compressor ZH and ZH+

Oil-free air centrifugal compressor ZH and ZH+ ZE&ZA (VSD) low pressure oil-free screw compressors

ZE&ZA (VSD) low pressure oil-free screw compressors.png) ZS (VSD+) oil-free rotary screw blowers

ZS (VSD+) oil-free rotary screw blowers ZB VSD+ oil-free centrifugal air blowers

ZB VSD+ oil-free centrifugal air blowers SF and SF+ oil-free scroll compressors

SF and SF+ oil-free scroll compressors AQ water-injected oil-free screw compressors

AQ water-injected oil-free screw compressors Oil-free booster air compressor ZD (VSD)

Oil-free booster air compressor ZD (VSD)Compressed gas solutions

Reciprocating gas compressors HX & HN

Reciprocating gas compressors HX & HN CO2 compressor

CO2 compressorNitrogen generators

NGM⁺ 7-70 nitrogen generator

NGM⁺ 7-70 nitrogen generator NGP⁺ PSA nitrogen generator

NGP⁺ PSA nitrogen generatorDryers and filter

MDG & MD & ND rotary drum dryers

MDG & MD & ND rotary drum dryers BD+CD+XD+ twin tower desiccant air dryers

BD+CD+XD+ twin tower desiccant air dryers FD refrigerated air dryer

FD refrigerated air dryer DD(+) and PD(+) oil coalescing filters

DD(+) and PD(+) oil coalescing filters Dust filtration for your air compressor

Dust filtration for your air compressor